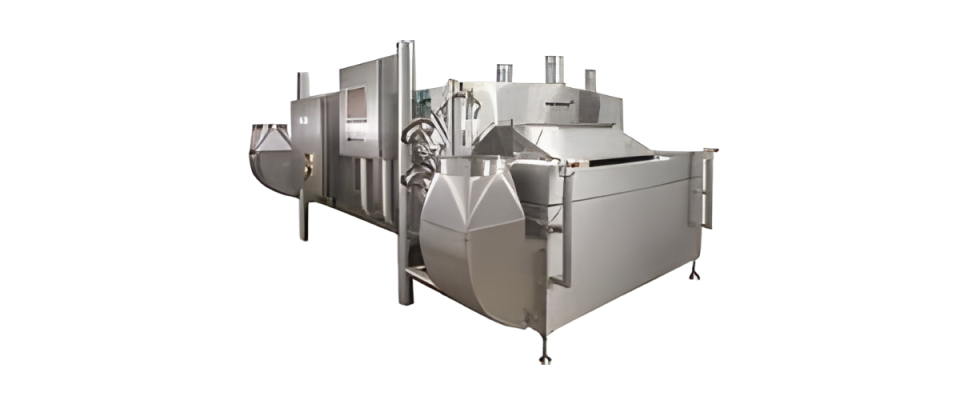

Messer is expanding its cryogenic technology footprint in protein processing as the upgraded KwikChiller returns to the IPPE 2026 show floor in Atlanta. The system now delivers both chilling and freezing functions, extending its role across high-throughput poultry and protein operations.

“After successful installations that demonstrated significant yield improvements in chilling poultry in combo bins,” said Don Smiley, Director of Food and Beverage at Messer. “We are excited to deploy the high-capacity KwikChiller for freezing applications — expanding our freezing equipment portfolio and its impact across protein processing value chain.”

Initially developed with poultry processors, the KwikChiller was engineered to replace manual CO₂ pellet use by providing rapid and uniform chilling in combo bins. Its demonstration at IPPE 2025 showed measurable yield improvements at a major poultry facility while offering an integrated exhaust system for safer CO₂ management.

“The recurring question from our customers in the 2025 Innovation Suite was, ‘Can the KwikChiller freeze too?’” continued Smiley. “We were proud to say yes – and we bring you the proof of KwikChiller’s versatility. We’ve validated that the KwikChiller delivers the high production rates and product quality our customers expect, all within a compact footprint that allows customers of varying scales of production to access this novel technology.”

The new configuration removes up to 30% more heat than standard freezers, boosting temperature uniformity for full freezing or cryo-assisted mechanical freezing. Its compact design also allows installation through a standard door, widening its applicability for processors with limited space.